(630) 682-4700

2655 Warrenville Road, Suite 225, Downers Grove, IL 60515

Better information about your collection, water, and stormwater systems

Explore ClarityBetter information about your collection, water, and stormwater systems

Explore Clarity

Mr. Griffiths, a certified Envision Sustainability Professional (ENV SP), has ...

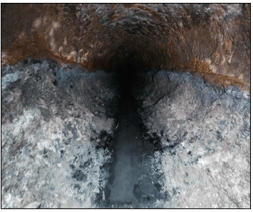

Approximately two decades ago, multi-sensor inspection (MSI) technologies were developed to overcome the challenges of inspecting large-diameter gravity sewers. These technologies have enabled utility owners to better understand asset conditions, make impactful, cost-effective decisions to maximize interceptor remaining useful life (RUL), and keep critical systems functioning efficiently. Twenty years of innovation and evolution have seen the application of MSI technologies expand to accommodate almost any pipeline environment.

So how can you leverage MSI technologies to evaluate your system’s condition? Here are three key things to consider before embarking on your MSI assessment.

What information do you need to gain from the assessment?

What information do you need to gain from the assessment?

Understanding the basic mechanics of different sensors and how the collected information will benefit a design engineer or your maintenance and capital planning programs is important. This will help you decide what technology will best achieve your condition assessment goals.

Most mobile phones have high-definition cameras–the latest iPhone includes a LiDAR sensor–so why would you accept anything less for your sewer inspection? Continuous scanning 3D LiDAR sensors are very affordable these days.

Most mobile phones have high-definition cameras–the latest iPhone includes a LiDAR sensor–so why would you accept anything less for your sewer inspection? Continuous scanning 3D LiDAR sensors are very affordable these days.

Sensor fusion is the secret sauce; blending multiple technologies can produce a single coherent picture of a pipeline using off-the-shelf sensors. At a bare minimum, you should require high-definition imagery and videos with good lighting.

Inspecting large-diameter interceptors is not for the faint of heart, and there is no one-size-fits-all when it comes to MSI technologies. Interceptors can span vast distances and are often in remote locations with deep access shafts, and that is without considering what is happening inside the pipe.

If flow volumes are high, a floating platform may be the best MSI technology.

If flow volumes are high, a floating platform may be the best MSI technology.Make sure that you do not have a laser focus on a specific technology or a specific feature, as this can limit the quality of your collected data and the decisions you are able to make from it.

New technologies are constantly being developed to comprehensively assess large-diameter assets. With a little forethought and an open mind, MSI technologies can help you make decisions that limit risk, enhance asset management, and extend RUL. RJN’s condition assessment and MSI experts are here to help you develop an inspection plan that uses the right tools for your pipeline and gain the knowledge you need. Reach out today!

Mr. Griffiths, a certified Envision Sustainability Professional (ENV SP), has ...